Many modelers experience all kinds of track and electrical problems

when building layouts using other major brands of N scale track. Many as

a last resort switch to Unitrack and experience spectacular results

running trains on a layout.

What are the reasons for this, one might ask?

Unitrack happens to be a well designed piece of equipment. The code 80 rail is mounted on a gray plastic roadbed which can easily be weathered and ballasted. The track comes in sections for all straight, curved, turnouts and odd sizes of track..

Unitrack uses a Uni-Joiner that locks one track section to another and this mechanism performs adequately for many years unlike regular rail joiners used by other major brands of track. These rail joiners tend to loosen and often require soldering to stay in place.

Unitrack turnouts, although limited in number perform flawlessly. The double crossover is a work of art and is one of the only double crossovers in N scale. Many users of other brands of track often use the Unitrack double crossover on their layouts.

Unitrack stays remarkably clean when compared to other brands of track. This is due to Kato composition of the nickel silver rails. Rarely do these rails accumulate the gunk and debris found on the brands of track after running trains for days at a time.

The curved sections of track come in radii that include 19" and 28 1/2" radii. A combination of these two radii produce a radii of 23-24" which is more than acceptable for sweeping curves on larger layouts.

The cost of Unitrack is comparable to other brands of track when the added purchase of cork road bed is needed.

Train operation on Unitrack is outstanding. No matter what size the layout,trains can run for hours at a time with no track or electrical issues. Users of Unitrack enjoy train operations without the added aggravations and frustrations experienced by users of other conventional brands of track.

Non users of Unitrack, buy Unitrack for test layouts. Trains run flawlessly on these "test ovals" and then return to problematic operation when the same trains are run on other major brands of track.

Unitrack can be set up easily and many different layout configurations can be "tested" in a short period of time.

Users of DCC find that their locomotives perform much better on Unitrack than on conventional track.

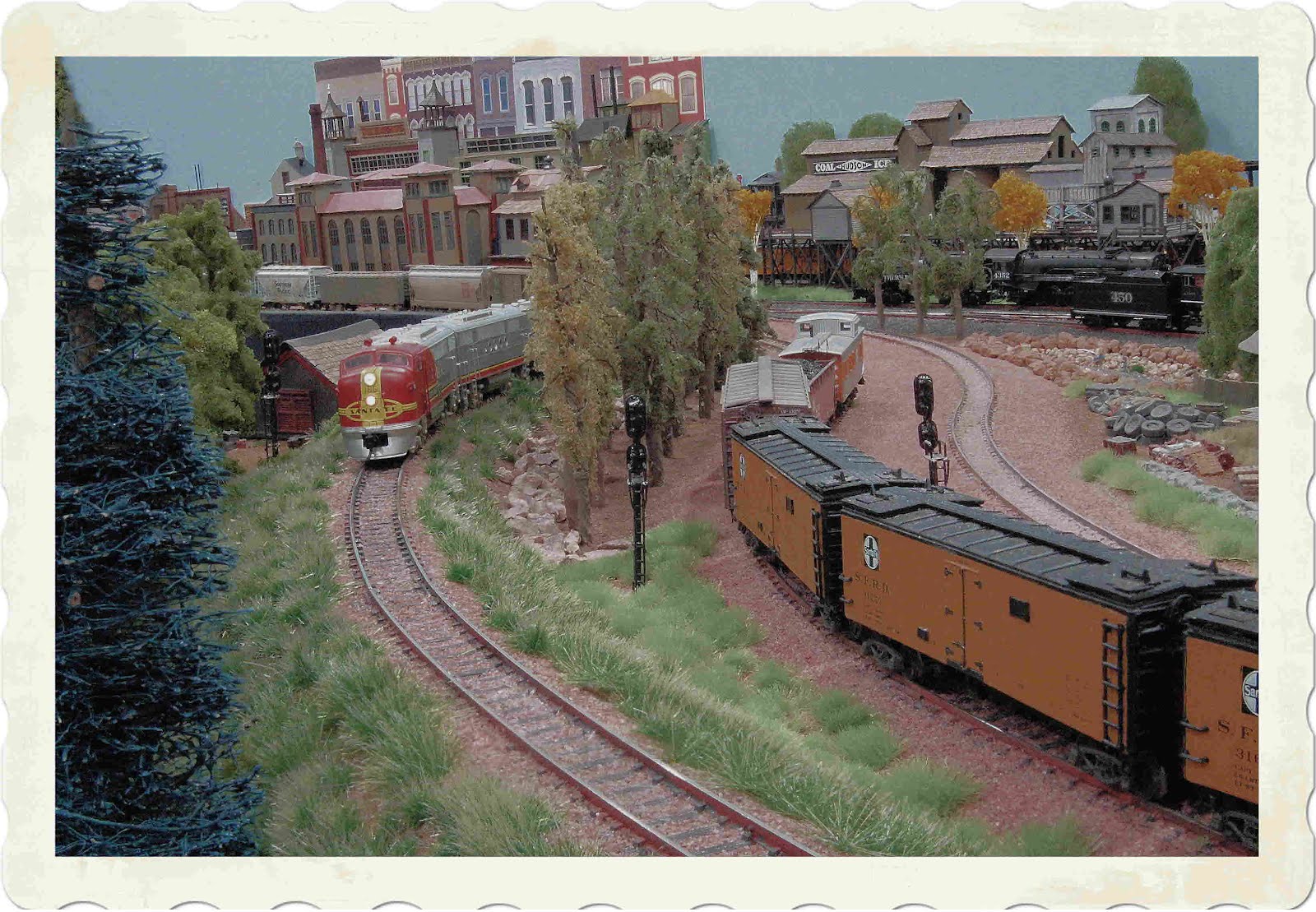

Unitrack can be used for any layout size. It;s no longer limited to "test ovals", and small layouts. I can attest to this fact as the "new" JJJ&E is a large layout by conventional standards. The "original JJJ&E , a layout on multiple levels (10x15') ran for over nine years without track or electrical issues. The layout on average was run daily for at least an hour in that time span.

The list goes on and on...

What are your thoughts about this subject? and how has Unitrack enhanced your enjoyment of running a layout?

What are the reasons for this, one might ask?

Unitrack happens to be a well designed piece of equipment. The code 80 rail is mounted on a gray plastic roadbed which can easily be weathered and ballasted. The track comes in sections for all straight, curved, turnouts and odd sizes of track..

Unitrack uses a Uni-Joiner that locks one track section to another and this mechanism performs adequately for many years unlike regular rail joiners used by other major brands of track. These rail joiners tend to loosen and often require soldering to stay in place.

Unitrack turnouts, although limited in number perform flawlessly. The double crossover is a work of art and is one of the only double crossovers in N scale. Many users of other brands of track often use the Unitrack double crossover on their layouts.

Unitrack stays remarkably clean when compared to other brands of track. This is due to Kato composition of the nickel silver rails. Rarely do these rails accumulate the gunk and debris found on the brands of track after running trains for days at a time.

The curved sections of track come in radii that include 19" and 28 1/2" radii. A combination of these two radii produce a radii of 23-24" which is more than acceptable for sweeping curves on larger layouts.

The cost of Unitrack is comparable to other brands of track when the added purchase of cork road bed is needed.

Train operation on Unitrack is outstanding. No matter what size the layout,trains can run for hours at a time with no track or electrical issues. Users of Unitrack enjoy train operations without the added aggravations and frustrations experienced by users of other conventional brands of track.

Non users of Unitrack, buy Unitrack for test layouts. Trains run flawlessly on these "test ovals" and then return to problematic operation when the same trains are run on other major brands of track.

Unitrack can be set up easily and many different layout configurations can be "tested" in a short period of time.

Users of DCC find that their locomotives perform much better on Unitrack than on conventional track.

Unitrack can be used for any layout size. It;s no longer limited to "test ovals", and small layouts. I can attest to this fact as the "new" JJJ&E is a large layout by conventional standards. The "original JJJ&E , a layout on multiple levels (10x15') ran for over nine years without track or electrical issues. The layout on average was run daily for at least an hour in that time span.

The list goes on and on...

What are your thoughts about this subject? and how has Unitrack enhanced your enjoyment of running a layout?